Reach out to see how cofaso® can help with your requirements.

Food & Beverage

cofaso® for the food and beverage industry

We Help You Engineer for Clean, Safe, and Continuous Production

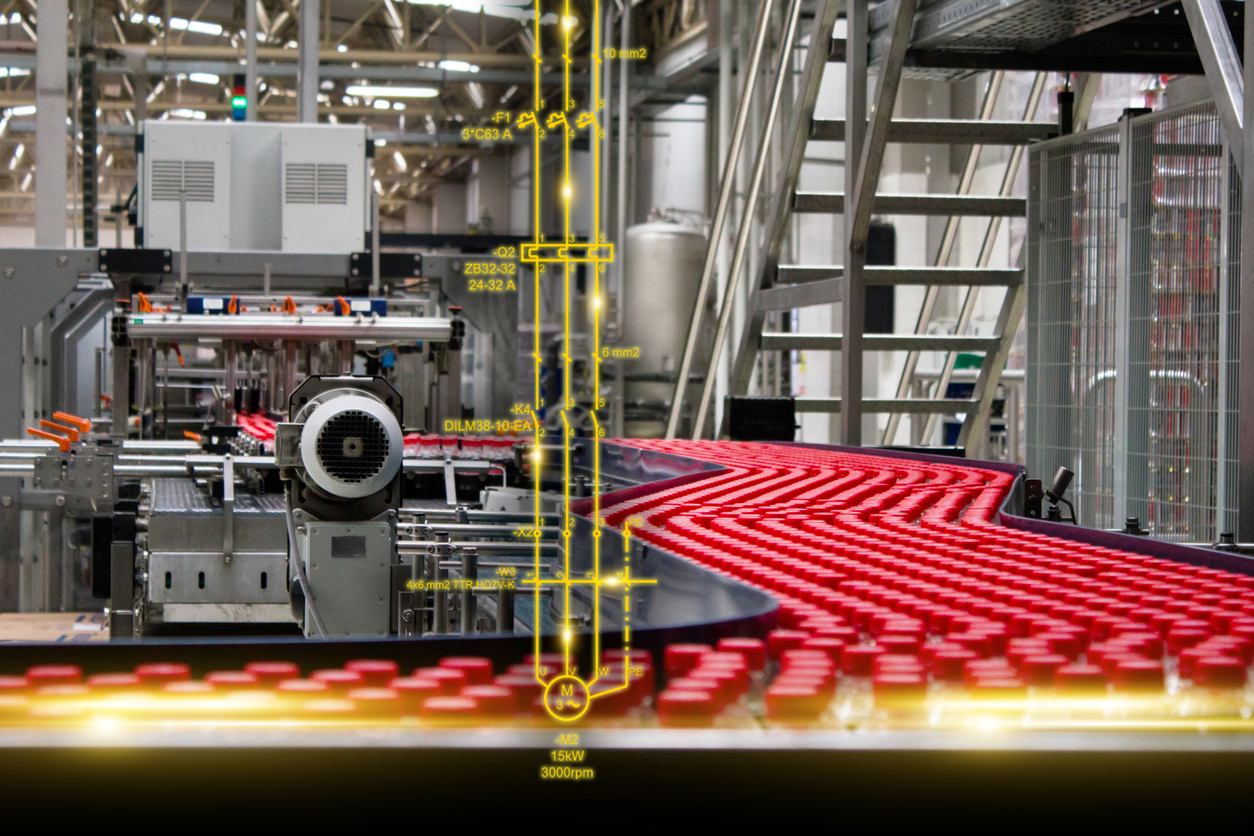

The food and beverage industry is characterized by its high demands on hygiene, safety, and uninterrupted production. In this fast-paced and highly regulated sector, automation and electrical engineering systems play a critical role in ensuring that every process—from raw material handling to packaging—is performed efficiently, traceably, and in compliance with strict food safety standards.

Behind every successful food processing line is a network of control panels, instrumentation, PLCs, and motor control systems that must operate reliably under demanding conditions. From temperature and flow control to batch tracking and line synchronization, the design and documentation of electrical and automation systems must be precise, maintainable, and ready for inspection at any time.

cofaso™ enables engineering teams to manage this complexity with a data-driven approach to electrical design—where consistency, documentation quality, and cross-department collaboration are built into every step of the process. The result: smarter design processes that support clean, safe, and cost-efficient production.

Electrical and Automation Engineering for the Food and Beverage Industry

In food production, downtime isn’t just inconvenient—it can lead to spoilage, contamination, and lost revenue. That's why engineering designs must not only be functional but also maintainable, auditable, and rapidly adaptable to production changes.

cofaso™ provides a structured environment for creating and managing all electrical documentation needed in food and beverage facilities, including:

- Motor control circuits for mixers, conveyors, pumps, and dosing systems

- PLC I/O wiring and device connection plans for sensors, actuators, and valves

- Terminal and cable plans for clean installation in hygienic environments

- Accurate loop diagrams for process control and CIP (Cleaning in Place) systems

With cofaso™, all this documentation can be generated automatically and updated centrally—reducing errors, improving traceability, and keeping production teams aligned with engineering.

Engineering Confidence in Every Batch

In an industry where product safety, cleanliness, and precision are vital, cofaso™ gives you the tools to engineer with confidence. By enabling structured design, accurate documentation, and seamless collaboration across departments, cofaso™ helps food and beverage manufacturers maintain compliance, reduce downtime, and ensure consistent product quality—batch after batch. cofaso™ helps engineering and maintenance teams deliver safe, efficient, and compliant solutions throughout the entire project lifecycle—from design to production to ongoing operations.

Key Benefits for the Food & Beverage Industry:

- Clean & Consistent Panel Design: Standardized electrical schematics, cabinet layouts, and terminal plans reduce complexity and support hygienic design practices.

- PLC and Device Connection Plans: Automatically generate detailed wiring plans for PLCs, sensors, actuators, and control devices—ensuring correct field connections.

- Automatic Manufacturing Reports: Generate wire lists and labeling data directly from the schematic—speeding up panel assembly.

- Change Management & Version Control: Track modifications clearly across production lines or batches, ensuring traceability and minimizing downtime during upgrades.

- Maintenance-Friendly Documentation: Provide maintenance and QA teams with complete, reliable documentation for troubleshooting, validation, and audits